MP35N

High-Performance Tubes

Industrial Suppliers Co., based in Tokyo, has been supplying cobalt-based alloys since the 1960s. We are proud to offer precision MP35N seamless tubes. Our commitment to quality, delivery, and cost, along with our engineering flexibility, has made our MP35N tubes a preferred choice for various industries.

Our MP35N tubes are accompanied by a certificate of compliance from the raw material suppliers, in accordance with ASTM F 562.

Features

Our proprietary drawn seamless MP35N tubes offer the following competitive advantages. All our MP35N tubes are proudly manufactured in Japan.

Precision

Tight dimensional tolerances for both outer and inner diameters, as well as wall thickness

Finish

Superior surface finish on both internal and external surfaces

Uniformity

Consistent wall thickness throughout the entire length of the tube

Performance

Exceptional tube performance facilitating fine-grained metallic structures

Thinness

Ultra-thin wall configurations achievable

.png)

Overview

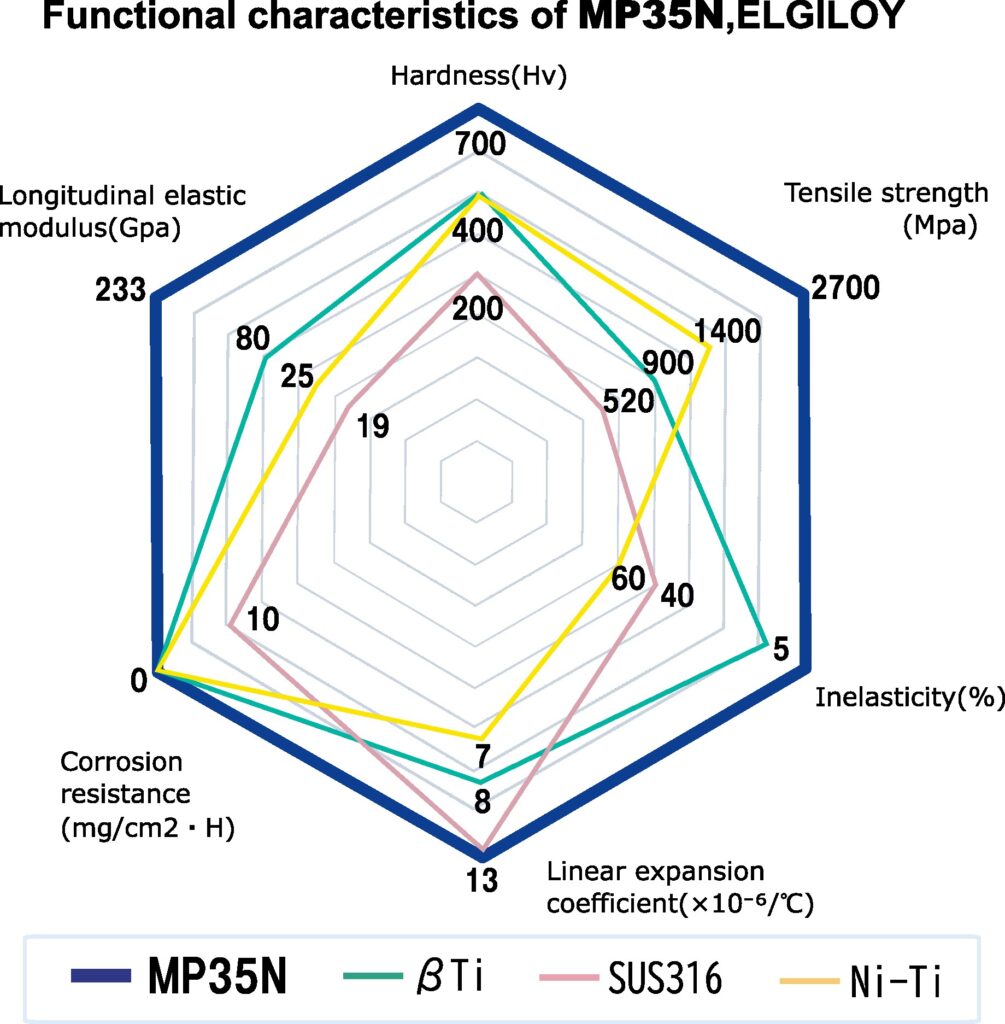

MP35N is a precipitation-hardenable nickel-cobalt-chromium-molybdenum alloy renowned for its exceptional strength, hardness, and outstanding corrosion resistance, particularly at elevated temperatures. This alloy combines ultra-high tensile strength, toughness, and ductility, while offering superior resistance to fatigue and stress corrosion cracking. It performs exceptionally well in harsh environments such as hydrogen sulfide, saltwater, chloride solutions, and seawater.

As a non-magnetic material, MP35N achieves ultra-high tensile strength through work hardening and aging processes. Its remarkable durability and versatility make it an ideal choice for demanding applications, including medical devices, dental products, electrical components, springs, and instrument parts in medical fields.

MP35N <Nominal Composition>

| C | Mn | Si | P | S | Cr |

|---|---|---|---|---|---|

| 0.025 Max | 0.15 Max | 0.15 Max | 0.015 Max | 0.015 Max | 19.0 -20.0 |

| Ni | Co | Mo | Fe | Ti | |

|---|---|---|---|---|---|

| 33.0 -37.0 | Bal. | 9.0 – 10.5 | 1.0 Max | 1.0 Max |

Mechanical Properties

| Material | Tensil Strength (MPa) | Yield Strength (Mpa) | Elongation (%) | Hardness (Hv) |

|---|---|---|---|---|

| MP35N, ELGILOY | 2940 | 5684 | 3 | 700 |

| β-TITANIUM | 1200 | 1100 | 10 | 400 |

| Ti 6Al-4V | 980 | 921 | 14 | 320 |

| Stainless Steel (304) | 655 | 260 | 56.9 | 187 |

Polishing

By performing internal polishing, we can achieve an inner surface finish of Ra 0.01µm or better.

Inner Diameter: From 0.1mm to 10mm, depending on the required finish

Length: 10mm to 2000mm

b-1024x592.png)

Get in Touch

Contact us today for detailed information or to request a quote. We are here to assist you with your precision tube needs. We speak your industry’s language and deliver precision solutions!

Contact

BANNER